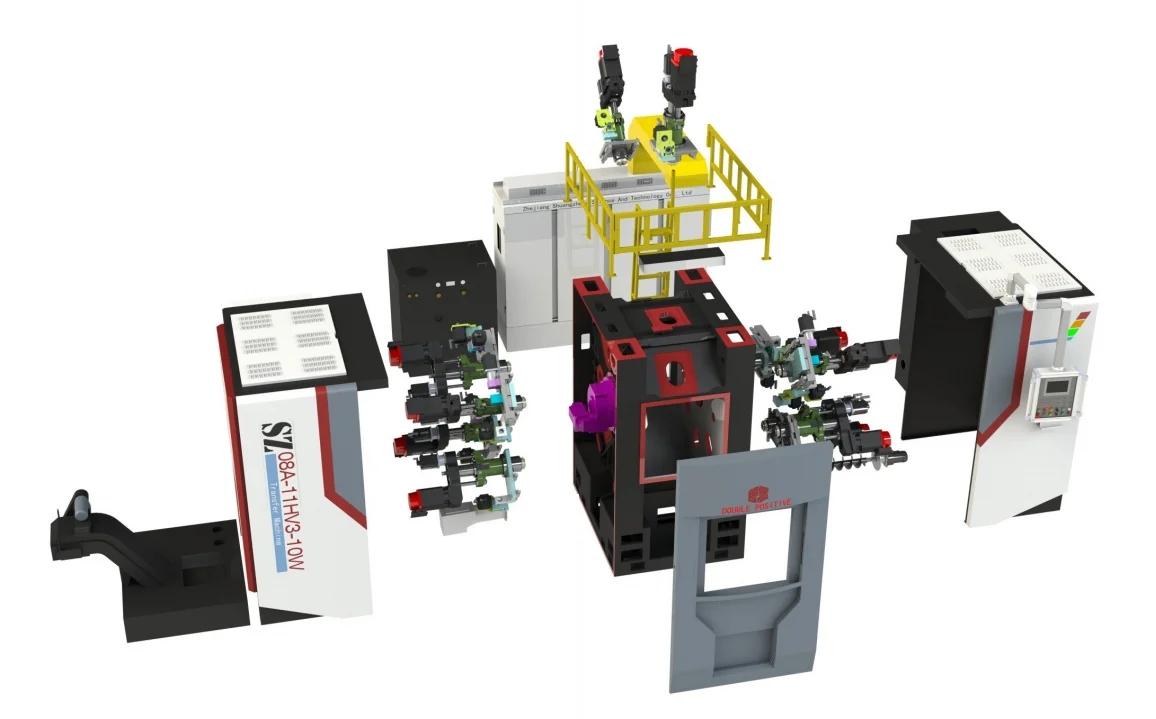

Automatic tool change system is a common and important part of Disc Type Special Machine, it can achieve fast and accurate tool change, improve machining efficiency and accuracy. This paper will introduce the working principle of automatic tool changing system and its application in Disc Type Special Machine.

The automatic tool changing system is composed of tool library, tool bar, tool sensor, tool interchanging mechanism, etc. It works as follows:

1. Tool library: Tool library is a device for storing tools, usually located on the side or rear of CNC machine tools. A number of tool positions are arranged in the tool library, each of which can be installed with a different type or specification of tools. The tool store is controlled by a motor drive or pneumatic device so that the tool can be accurately removed or put back.

2, tool bar: tool bar is connected to the cutting tool and spindle device. There is a tool interface on the tool bar to fix the tool. The tool lever is controlled by servo motor or hydraulic cylinder to realize the loading and unloading operation of the tool.

3, tool sensor: Tool sensor is used to detect the position and status of the tool. It can monitor in real time whether the tool is installed in place, the length and diameter of the tool through devices such as photoelectric switches, pressure sensors or encoders. This information will be transmitted to the CNC system to ensure the accuracy of the cutting operation.

4, tool exchange mechanism: Tool exchange mechanism is a key component to achieve the rapid replacement of tools. It is usually composed of a clamping mechanism, a tool changing arm and a tool changing mechanism. When a tool needs to be replaced, the tool exchange mechanism removes the currently used tool and takes the new tool out and assembles it to the tool holder.

Disc Type Special Machine

Automatic tool changing system plays an important role in Disc Type Special Machine. Its main advantages include:

1, improve production efficiency: automatic tool change system can quickly and accurately replace the tool, reduce the tool change time, improve production efficiency. Workers do not need to manually participate in the tool change process, which can save a lot of human resources.

2, improve the machining accuracy: the tool sensor can monitor the position and status of the tool in real time to ensure that the assembly of the tool is accurate. The automatic tool changing system eliminates the influence of human factors on cutting precision and improves the precision and consistency of machining.

3, rich processing capacity: automatic tool change system makes the machine can accommodate a number of different types or specifications of tools. In this way, the operator can choose the right tool for processing according to the specific requirements, improving the processing capacity and flexibility of the machine tool.

In short, automatic tool change systems are a common and important part of Disc Type Special machines. Through the collaboration of parts such as tool library, tool bar, tool sensor and tool interchange mechanism, the automatic tool changing system can quickly and accurately change tools, improve production efficiency and machining accuracy. In modern manufacturing industry, automatic tool changing system has become one of the important means to improve production efficiency and product quality.

Disc Type Special Machine https://www.zjshuangzheng.com/Disc-Type-Special-Machine.html