At present, there are three categories of people who are just engaged in rotary boring tapping cutting special machine. One is the operator, who was previously engaged in the general manual machine tool or semi-automatic machine tool operation of technical workers, they are very familiar with machining, but for the turn-milling compound CNC lathe programming is relatively unfamiliar, which accounts for a large part; The other was a student who had just graduated from the mechanics school. They are familiar with the theory of machining, CNC machining and programming, but lack practical experience in machining. Some of these operators have never been exposed to machining and programming, so it is difficult for them to learn how to operate CNC machines. For these beginners rotary boring tapping cutting special machine personnel, it is important to master some rotary boring tapping cutting special machine operation skills.

So how can we improve ourselves quickly for beginners?

On the one hand, it can avoid the collision accident of machine tool and cause the damage of machine tool; Second, in a short period of time, it can quickly improve the operator's rotary boring tapping cutting special machine operation skills, competent for their work, and create economic benefits for the unit.

Today, especially for these people who have just come into contact with CNC machine tool operators for CNC training, I introduced some theoretical knowledge of rotary boring tapping cutting special machine skills, mainly understand CNC machine tools, control CNC machine tools, rotary boring tapping cutting special machine program editing, processing skills are analyzed in four aspects. Hope to just engaged in rotary boring tapping cutting special machine operation has a certain reference significance.

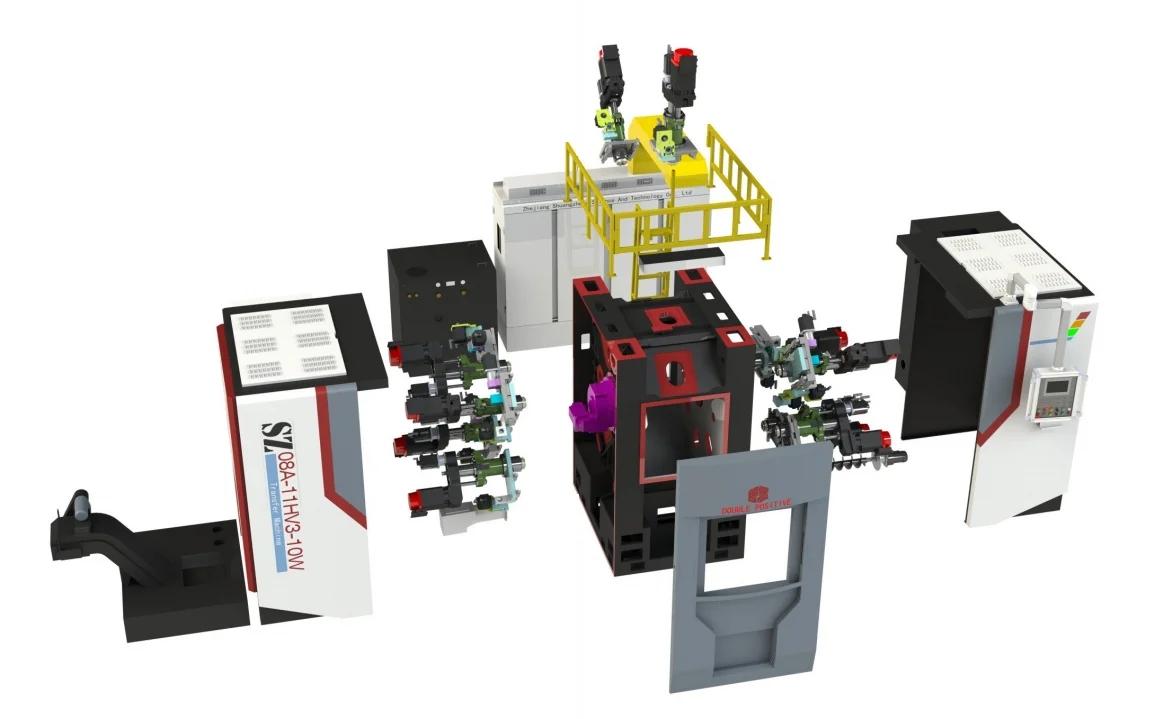

First, the operator of the CNC lathe manufacturer needs to have an understanding of the rotary boring tapping cutting special machine in operation. Understand the mechanical structure of the machine: understand the mechanical structure of the machine; Master the shafting distribution of machine tools; More firmly grasp the rotary boring tapping cutting special machine in the positive and reverse axis direction; Master the functions and uses of each part of the machine tool, such as the principle and function of the simple pneumatic system, the working principle and function of the simple hydraulic system; In addition to mastering the working principle and function of the auxiliary unit of the machine tool, such as the working principle, function and use of the unit such as the knife library, cooling unit, regulator, electric cabinet cooler, etc., the working principle, function and use of the door lock of the machine tool. Firmly grasp the function of the operation button of the machine: know how to execute the program; How to pause the program and check the processing state of the workpiece, restore the suspended state and continue to execute the program, how to stop the program; How to change a program and then execute it, and so on.

Know the operating system of the machine you are operating; Simple understanding of the control principle and working method of CNC system; Which working language is used in the system, the software used in the machine, and the language used. If the operator does not know the language or the language of the professional vocabulary does not understand, then you need professional training, in the training you need to carefully take notes, what Chinese meaning each word in the machine tool software represents, remember to master, in order to use the machine tool correctly in the future work. In addition, operators also need to learn and master the routine operation alarm instructions during the training process to understand the Chinese meaning of their representation, how to solve problems and how to eliminate false alarms. In addition, for the operator, if you have the strength and ability to allow, you can learn and master this language, so it will be very helpful to improve the operating skills of the machine in the future.

Secondly, to master the manual or automatic operation control of rotary boring tapping cutting special machine, skilled control of rotary boring tapping cutting special machine axis motion. The operator recommends reaching a state of good practice so that it is free to open and close under any circumstances. Only in the event of a collision or failure, the operator can deal with the problem correctly and in a timely manner, and the operator will form a conditioned reflex and take a decisive brake. In addition, the operator of rotary boring tapping cutting special machine should be very familiar with the machining procedure; What kind of process and operation, what kind of action the machine should have, should be very familiar. When the machine executes the program, you can know at the time whether the machine is acting correctly and whether the braking action is taken. In addition, every beginner operator is more or less afraid of the psychology when starting to operate the machine, afraid of machine collision, collision. Therefore, only operators skilled in the operation of Fukushima rotary boring tapping cutting special machine can overcome similar fears. In order to learn and master higher rotary boring tapping cutting special machine operation skills on this basis.

rotary boring tapping cutting special machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html